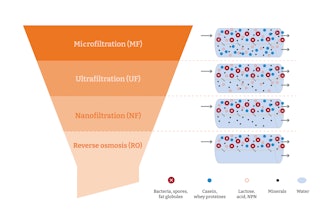

Overview of the membrane processes

Membrane processes in the food industry

Microfiltration (MF) removes bacteria and separates out macromolecules, making it ideal for reducing bacteria in skimmed milk, whey and brine. It also defats whey to produce whey protein concentrate (WPC).

Ultrafiltration (UF) concentrates large molecules such as proteins. It is used in milk and whey for concentration, and for protein standardisation for cheese, yoghurt and other products. It is also used to clarify fruit and berry juices.

Nanofiltration (NF) concentrates organic components by removing monovalent ions such as sodium and chlorine (partial demineralisation). It is used for the partial demineralisation of milk, whey and UF permeate/retentate.

Reverse osmosis (RO) concentrates solutions by removing water. It is used for dewatering milk, whey and UF permeate or condensate, among other things.

Optimum cleaning for maximum productivity

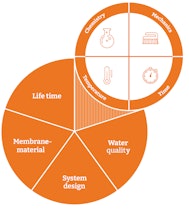

High processing capacity and productivity are crucial for the profitability of your business. We will help you optimise the most important factors in membrane cleaning.

The Sinner's Circle describes the cleaning parameters: Time, chemistry, temperature and mechanics. In practice, these often have to be adapted, e.g. for gentler cleaning using fewer chemicals and longer exposure times.

Membrane cleaning is more complex than conventional CIP processes, and requires optimal conditions:

- Water quality (hardness and SDI value)

- System design

- Membrane material

- Service life

- Chemical oxygen demand (COD)

Gentle but effective membrane cleaners

Most membranes are sensitive to chemical and physical influences, do not tolerate high temperatures, and also act as filters during cleaning. A good membrane cleaner must fulfil the following criteria:

- Low aggressiveness on various membrane materials

- High chemical activity for effective cleaning performance

- Residue-free rinsing, no deposits on the membranes

- Effective against a wide range of soiling

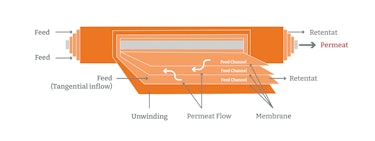

How cross-flow filtration works

The tangential flow process is a filter process that is mostly used in the dairy and beverage industry. A suspension (liquid with dispersed solids) is fed into the inlet. It is pumped tangentially (sideways) past the filter medium at a speed of 2.5 to 3 metres per second. Part of the suspension flows through the filter as permeate; the remaining part is called retentate.

The liquid must flow fast enough to prevent deposits (covering layers or fouling; see glossary) from forming on the membrane.

Lexicon of membrane cleaning

- Biofilm or biofouling can be cleaned using enzymatic products

- Covering layer: Deposition and accumulation of feed components on the membrane surface and/or in the pores of the membrane

- Depending on the type, membranes are made of different materials, which are classified as organic (e.g. cellulose, polypropylene, polyethylene) or inorganic (e.g. stainless steel, carbon, silicon carbide)

- Enzymatic cleaners: remove proteins from thin composite membranes

- Flux refers to the filtration rate of permeate, measured in liters per square meter of membrane surface per hour (l/m2/h)

- Plastic: Polyamide, polyvinyl difluoride, polyvinyl acetate, polyethylene, polypropylene or polysulfone are common organic membrane types

- System design

FAQ

Membrane cleaning

Membrane cleaning is a critical process for many companies. Perhaps you have already considered these questions: