One of my international customers produces almost a million soft baked goods every day with just one plant and one line. It was our hygiene concept that made this possible – and I’m proud of that.

Key Account Manager and Master BakerIndustrial baking line

Lerades CM 401

Chlorine-based surface disinfectant for spraying, foam-free.

Lerapur SR 115

Alkaline foam cleaning agent for the daily cleaning

of machines, appliances, walls and floors. Excellent foaming properties and good protein & grease dissolving capacity.

Lerasept FP 408

Alcohol-based surface disinfectant for sensitive production areas and surfaces and machines that come into contact with products. Halal-certified.

Lerapur ASR

Mildly alkaline foam cleaner for sensitive surfaces.

Lerasept FP 408

Alcohol-based surface disinfectant for sensitive production areas and surfaces and machines that come into contact with products. Halal-certified.

Lerasept HD

Alcohol-based hand disinfectant for all production areas.

Lerades CM 401

Chlorine-based surface disinfectant for spraying, foam-free.

Lerapur SR 115

Alkaline foam cleaning agent for the daily cleaning of machines, appliances, walls and floors. Excellent foaming properties and good protein & grease dissolving capacity.

Lerasept FP 408

Alcohol-based surface disinfectant for sensitive production areas and surfaces and machines that come into contact with products. Halal-certified.

Lerapur ASR

Mildly alkaline foam cleaner for sensitive surfaces.

Lerasept FP 408

Alcohol-based surface disinfectant for sensitive production areas and surfaces and machines that come into contact with products. Halal-certified.

Lerasept HD

Alcohol-based hand disinfectant for all production areas.

FAQ

Expert questions

Are you a baker, confectioner, production manager, development manager or QM manager? If so, then you may have already asked yourself the following questions:

<% question %>

<%# image.publicUrl %>Industry specialities

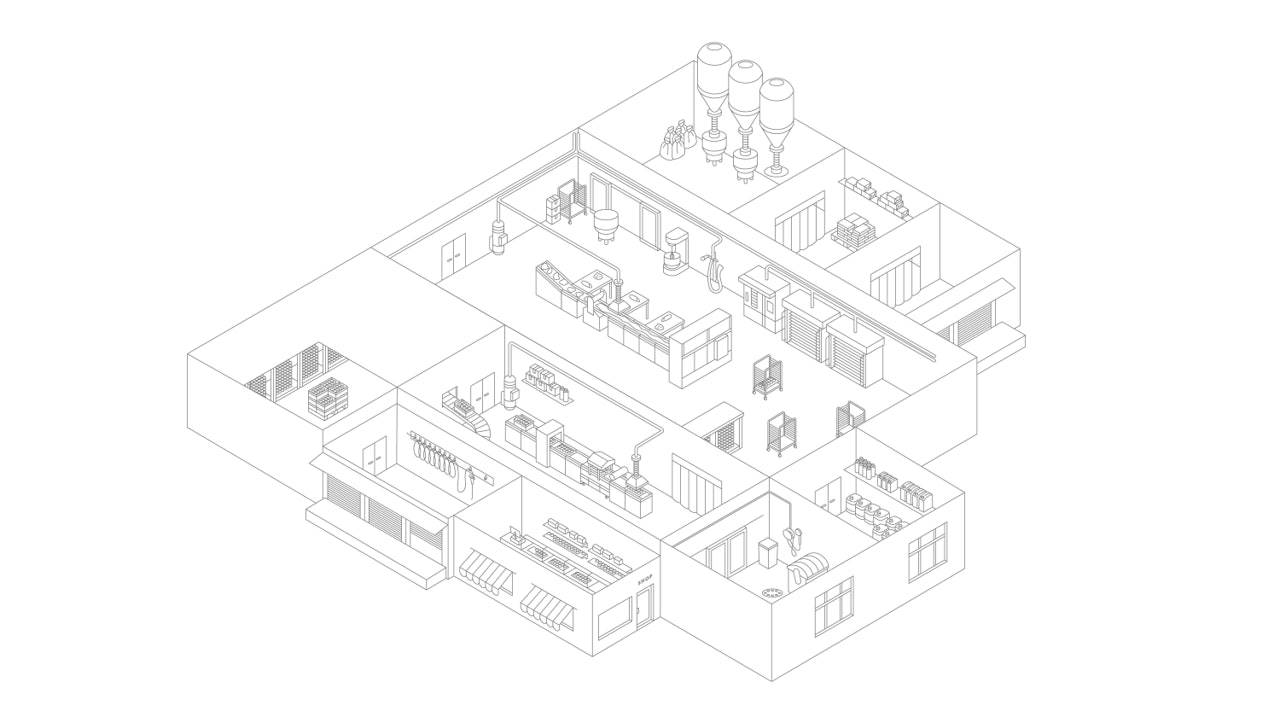

1. Sales areas

Whether on the sales floor or in production, hygiene is always the top priority. After all, your visible surfaces are the first part of your business your customers will notice. Transport trolleys for dough and rack trolleys for dough pieces or finished baked goods must be spotlessly clean. Our hygiene plans will help your sales staff comply with the regulations, so you pass your HACCP audit.

2. Crate washing

CIP systems for crates are subjected to heavy use in bakeries due to egg whites and starch from flour and dough residues. All your parameters must be correct to ensure your crate washer functions perfectly as a closed-loop system. Your disinfection process for container cleaning must reach the required 82°C. You need to know exactly how much water your system consumes and the correct concentration for your cleaning agents. The wetting of your containers must be up to standard. Your nozzles must also be set correctly so they don’t cause any unwanted spray patterns to form. Our experts will be happy to advise you on your optimisation options.

3. Machinery for the production of baked goods

4. Machinery for pasta production

Clean performance, clear benefits

Service & Support

Our Experts in Europe